- 您现在的位置:买卖IC网 > Sheet目录134 > M1MA174T1G (ON Semiconductor)DIODE SW SS 200MA 100V SOT-323

�  �

�

� �  �

�

� �  �

�

� � M1MA174T1�

� � http://onsemi.com�

� � 4�

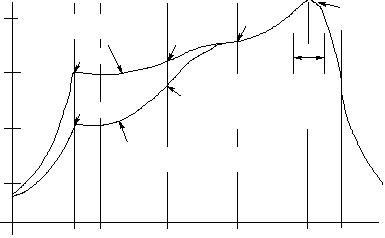

� � STEP 1�

� � PREHEAT�

� � ZONE 1�

� � �

� � STEP 2�

� � VENT�

� � �

� � ZONES 2 & 5�

� � STEP 3�

� � HEATING�

� � �

� � STEP 4�

� � HEATING�

� � ZONES 3 & 6�

� � ZONES 4 & 7�

� � �

� � STEP 5�

� � HEATING�

� � �

� � STEP 6�

� � STEP 7�

� � VENT�

� � COOLING�

� � 200°C�

� � 150°C�

� � 100°C�

� � 50°C�

� � TIME (3 TO 7 MINUTES TOTAL)�

� � TMAX�

� � SOLDER IS LIQUID FOR�

� � 40 TO 80 SECONDS�

� � (DEPENDING ON�

� � MASS OF ASSEMBLY)�

� � 205°�

� � TO 219�

� � °C�

� � PEAK AT�

� � SOLDER JOINT�

� � DESIRED CURVE FOR LOW�

� � MASS ASSEMBLIES�

� � 100°C�

� � 150°C�

� � 160°C�

� � 140°C�

� � Figure 5. Typical Solder Heating Profile�

� � DESIRED CURVE FOR HIGH�

� � MASS ASSEMBLIES�

� � 170°C�

� � For any given circuit board, there will be a group of�

� � control settings that will give the desired heat pattern. The�

� � operator must set temperatures for several heating zones,�

� � and a figure for belt speed. Taken together, these control�

� � settings make up a heating aprofileo for that particular�

� � circuit board. On machines controlled by a computer, the�

� � computer remembers these profiles from one operating�

� � session to the next. Figure 7 shows a typical heating profile�

� � for use when soldering a surface mount device to a printed�

� � circuit board. This profile will vary among soldering�

� � systems but it is a good starting point. Factors that can�

� � affect the profile include the type of soldering system in�

� � use, density and types of components on the board, type of�

� � solder used, and the type of board or substrate material�

� � being used. This profile shows temperature versus time.�

� � SOLDER STENCIL GUIDELINES�

� � Prior to placing surface mount components onto a printed�

� � circuit board, solder paste must be applied to the pads. A�

� � solder stencil is required to screen the optimum amount of�

� � solder paste onto the footprint. The stencil is made of brass�

� � or stainless steel with a typical thickness of 0.008 inches.�

� � The stencil opening size for the surface mounted package�

� � should be the same as the pad size on the printed circuit�

� � board, i.e., a 1:1 registration.�

� � TYPICAL SOLDER HEATING PROFILE�

� � The line on the graph shows the actual temperature that�

� � might be experienced on the surface of a test board at or�

� � near a central solder joint. The two profiles are based on a�

� � high density and a low density board. The Vitronics�

� � SMD310 convection/infrared reflow soldering system was�

� � used to generate this profile. The type of solder used was�

� � 62/36/2 Tin Lead Silver with a melting point between�

� � 177±189°C. When this type of furnace is used for solder�

� � reflow work, the circuit boards and solder joints tend to�

� � heat first. The components on the board are then heated by�

� � conduction. The circuit board, because it has a large surface�

� � area, absorbs the thermal energy more efficiently, then�

� � distributes this energy to the components. Because of this�

� � effect, the main body of a component may be up to 30�

� � degrees cooler than the adjacent solder joints.�

� 发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

M5010035V

MODULE POWER 100A 1200V SCR BRDG

MBR0520LT3

DIODE SCHOTTKY 0.5A 20V SOD-123

MBR0520L

DIODE SCHOTTKY 0.5A 20V SOD-123

MBR0530

DIODE SCHOTTKY 30V 0.5A SOD-123

MBR0540

DIODE SCHOTTKY 40V 0.5A SOD-123

MBR1035

DIODE SCHOTTKY 10A 35V TO-220AC

MBR1060

DIODE SCHOTTKY 10A 60V TO220-2

MBR1080

DIODE SCHOTTKY 10A 80V TO-220AC

相关代理商/技术参数

M1-MA-EA-AJ

制造商:Johnson Electric / Saia-Burgess 功能描述:3position lowdepth random key lockswitch 制造商:Johnson Electric / Saia-Burgess 功能描述:KEY SW./2 3POS. RAND.KEY 制造商:Saia Burgess 功能描述:KEY SW./2 3POS. RAND.KEY

M1MAWAT1

制造商:LRC 制造商全称:Leshan Radio Company 功能描述:Common Anode Silicon Dual Switching diodes

M1MCAAAE

制造商:Johnson Electric / Saia-Burgess 功能描述:KEYSWITCH DPDT 2 POS RANDOM KEY

M1-MC-AA-AE

制造商:Johnson Electric / Saia-Burgess 功能描述:DPCO random key+trapping lock switch

M1MCAAAE

制造商:Johnson Electric / Saia-Burgess 功能描述:KEYSWITCH DPDT 2 POS RAND KEY

M1MFM 60 MINS

制造商:BROYCE CONTROL ENGINEERING 功能描述:MULTI FUNCTION TIMER

M1MFM 60MINS

制造商:BROYCE CONTROL 功能描述:MULTI FUNCTION TIMER (4) 制造商:BROYCE CONTROL 功能描述:MULTI FUNCTION TIMER (4), Contact Configuration:SPDT, Time Min:0.5s, Time Max:10

M1MFT 24/110V

制造商:BROYCE CONTROL 功能描述:TIMER MULTIFUNCTION 4 FUNCTION 制造商:BROYCE CONTROL 功能描述:TIMER, MULTIFUNCTION, 4 FUNCTION 制造商:BROYCE CONTROL 功能描述:TIMER, MULTIFUNCTION, 4 FUNCTION, Contact Configuration:SPCO, Nom Input Voltage: